Copyright © Dafeng Forming Technology Co., Ltd. All Rights Reserved. Site Map

- +86-18962598944

- 15862600622@163.com

- No. 8299 Changbai Road, High tech Park, Hexin Town, Lvyuan District, Changchun City

On December 29, 2024, the CR450 EMU prototype was officially released in Beijing, marking a major breakthrough in the "CR450 Science and Technology Innovation Project". The project was led by China State Railway Group Co., Ltd. and jointly tackled by the "Railway Science and Technology Innovation Alliance" composed of domestic enterprises, universities and research institutes such as CRRC. The CR450 EMU prototypes released this time include two prototypes, CR450AF and CR450BF, with a test speed of 450 kilometers per hour and an operating speed of 400 kilometers per hour.

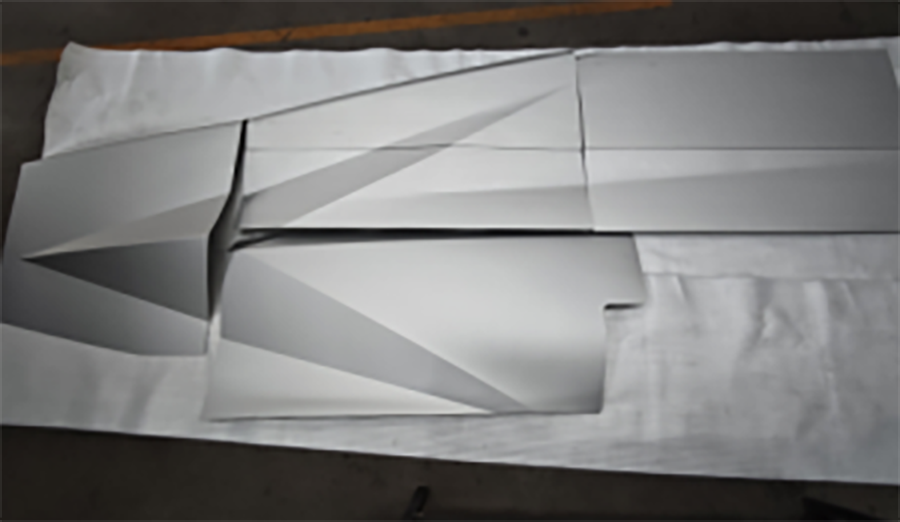

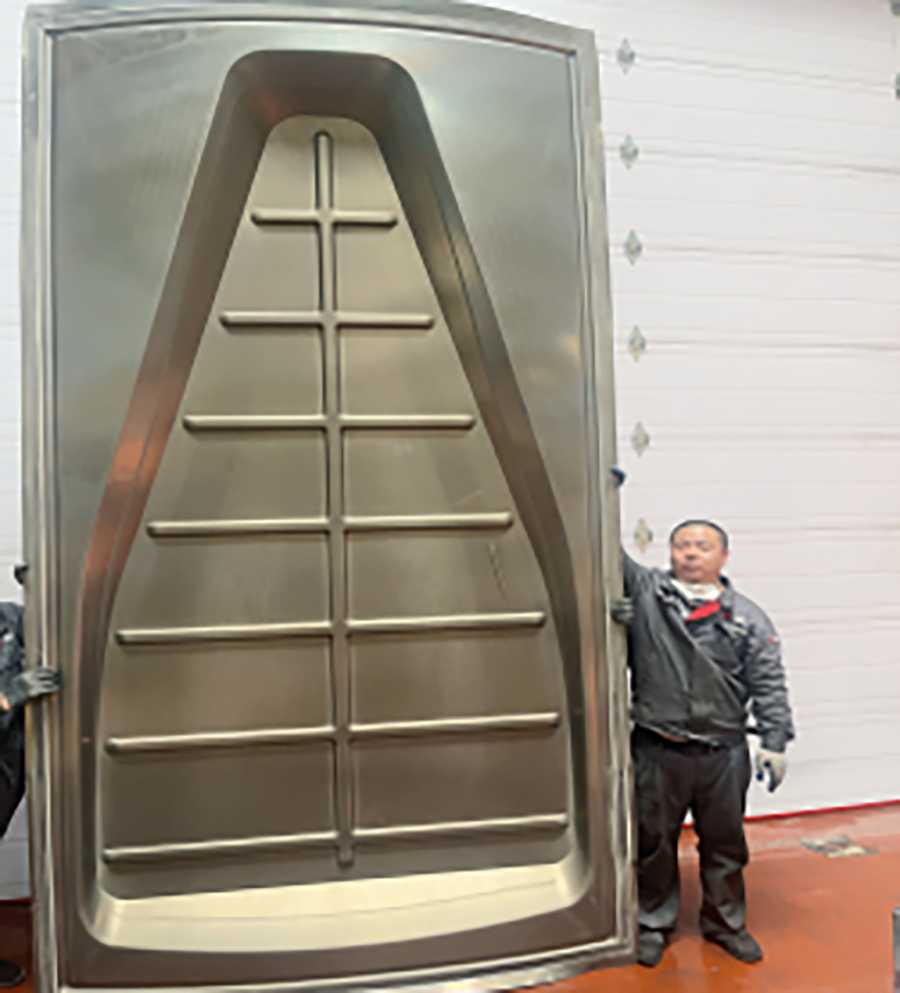

Since 2016, the large-size thin-walled complex-shaped aluminum alloy plates developed by Professor Wang Guofeng's team at Harbin Institute of Technology have been widely used in the rail transit industry, providing a new forming process solution for the design of high-speed rail head solutions. With the support of rapid superplastic forming technology, the aluminum alloy skin solution can achieve a weight reduction target of at least 15%, with significant lightweight and environmental protection advantages. At present, Dafeng Forming Technology Co., Ltd., a company that transforms technological achievements, is a qualified supplier of superplastics for CRRC Sifang and Changchun Railway Vehicles. It has successfully applied superplastic forming technology in multiple projects, effectively reducing the number of parts, shortening the welding time, and reducing the weight of the entire vehicle.

This time, Dafeng Forming participated in the development of key aluminum alloy parts for the front of the CR450 EMU, including the left and right side walls of the CR450AF front and the left and right side walls of the CR450BF front. This is not only another successful case in promoting the industrialization of superplastic forming, but also demonstrates its technical strength and innovation capabilities in the field of rail transit. Dafeng Forming will continue to strengthen its independent innovation capabilities and improve its service level with a professional and focused attitude, and contribute to the strategy of building a strong manufacturing country.