Copyright © Dafeng Forming Technology Co., Ltd. All Rights Reserved. Site Map

- +86-18962598944

- 15862600622@163.com

- No. 8299 Changbai Road, High tech Park, Hexin Town, Lvyuan District, Changchun City

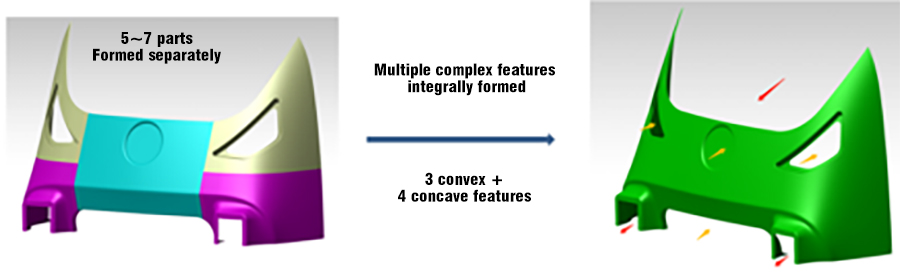

The headlight socket is designed with 3 convex and 4 concave features. The original technical solution was to form 5-7 parts separately and then weld them together. After the introduction of rapid superplastic forming technology, the overall forming of multiple deep cavities was achieved, and one part was successfully used for replacement.

The overall cab front skin after the introduction of rapid superplastic forming has the following advantages:

· Only 5 large skin parts are needed to form

· The skin welding time is shortened from the original 6 days to 2 days

· The welding deformation is small while improving the strength of the overall front

· A 30% weight reduction effect can be achieved (compared with the fiberglass skin solution)

Currently, this model has been officially mass-produced and delivered 100 sets, and the product quality and advanced technology have been highly praised by customers.

Note: Please refer to the following figure